Modern manufacturing demands sophisticated analytical approaches for effective decision-making and process optimization. The implemented analytical suite combines three powerful tools that work together to provide comprehensive insights into production processes.

The Monte Carlo analysis module enables precise probability assessment and experimental result tracking, helping predict outcomes and optimize manufacturing parameters. This statistical approach proves particularly valuable for complex production scenarios where multiple variables interact.

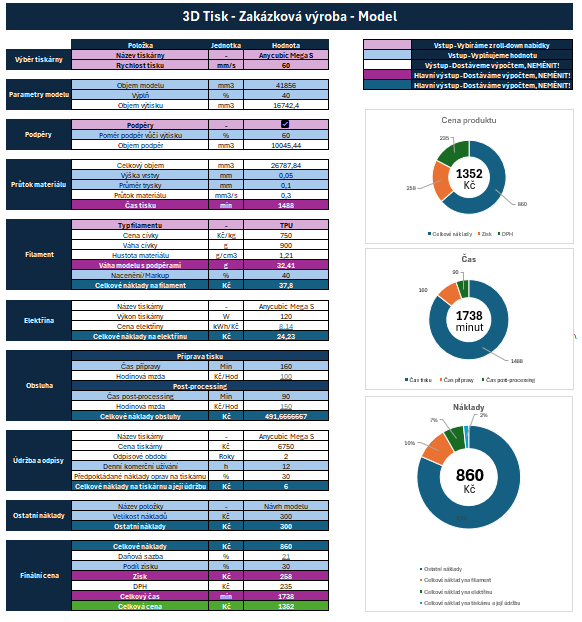

A detailed 3D printing cost analysis system offers comprehensive breakdowns of production expenses, encompassing materials, time utilization, and overall costs. This granular approach to cost tracking helps identify optimization opportunities and ensures profitable production runs.

The sensitivity analysis tool completes the suite by modeling various scenarios with percentage variations, demonstrating how different variables impact key business metrics. This capability proves essential for risk assessment and strategic planning in manufacturing operations.

This integrated analytical approach provides manufacturers with the insights needed to optimize processes, reduce costs, and make data-driven decisions in today’s competitive industrial environment.